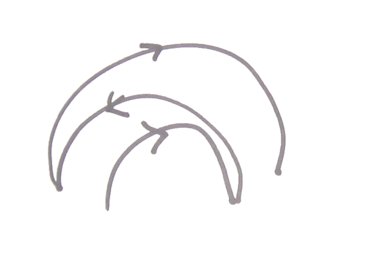

I keep looking this up on YouTube, so figured I’d link to it on my blog so I don’t have to remember where to find it 😉

I might sew one of these today…

The main part starts at about 2 minutes in.

Later the same day…

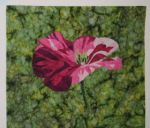

I had a green batik jelly roll I picked up in Bali last September. I have three baby quilts to make, so thought I’d use this technique and that jelly roll for the quilt tops.

Here’s all those strips sewn into one long 1600″ strip:

However, I was disappointed in the final result.

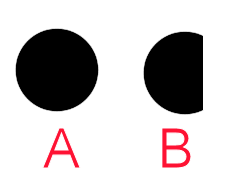

I think there were a couple of reasons — the jelly roll seemed to have a lot of medium and dark fabrics and not many lights, and the technique of just grabbing them off the roll in the order they were in meant that like colours were stitched together giving double strips of the same fabric; even where different fabrics were joined, the contrast wasn’t enough to be noticeable (see picture below where there are two strips that have joins).

Had I realised this earlier, I might have started again and mixed in the pink jelly roll strips with the green (the yellow is to be used for something else) or deliberately picked a light, then medium, then dark, the light again etc. instead of stitching them straight off the roll as per the instructions in the video.

While this took me longer than an hour (probably about two hours), it was a very quick way to make a quilt top. I have enough to make four baby quilt tops, but as I’m not happy with the effect (I just got stripes, not that slashing effect that you see in the video), I may well use what I made as the backs for the baby quilts. And as I’ve sewn and cut down the finished top to about 25″ wide, I’ll use one of the clever techniques for backs that Elizabeth Hartman shares on her free Craftsy lesson to make the backs a bit bigger: http://www.craftsy.com/class/creative-quilt-backs/117

I was glad I tried this technique and would use it again, but next time I’ll be more careful about the fabric contrasts in the jelly roll and perhaps pick and choose what fabric goes with what, instead of just doing them in the order they are on the roll.

Update: There’s a new Jelly Roll Race video, showing how to add little squares between the ends of each jelly roll strip: